The resulting depth of carburization, commonly referred to as case depth, depends on the carbon potential of the medium used and the time and temperature of the carburizing treatment. Its not bone charcoal-colored, or chemical case hardening, and is not even hardening at all. A STEM-focused institution, it focuses on polymers, advanced materials, and engineering. This article described the primary methods of steel surface hardening. Small items may be case-hardened by repeated heating with a torch and quenching in a carbon rich medium, such as the commercial products Kasenit / Casenite or "Cherry Red".  Carbonitriding is similar to cyaniding except a gaseous atmosphere of ammonia and hydrocarbons is used instead of sodium cyanide. This carbon accumulation in the surface layer is also called carburisation. Atomic nitrogen reacts with the metal to increase its hardness and resistance. The quenching required for this can be either done. The Upland Shooting Life, by George Bird Evans, New England Grouse Shooting, by William Harnden Foster, The Processes of Color Case Hardening and Heat Treating #022 of the Gun Room Podcast, The Difference Between a Deutsch-Drahthaar and a German Wirehaired Pointer, Understanding Shotgun Chokes How to Choose a Choke Size for Hunting, Pheasant Hunting Ammo and Chokes A Pheasant Hunters Guide, 28-Gauge: The Exception of the Sub-Gauge Shotgun, German Shorthaired Pointer The Most Popular Versatile Dog in the World, Pudelpointer Dog Breed Form, Function, History, and More, Gordon Setter Breed History, Standards and Origins, Development and History of the Irish Red Setter, Irish Water Spaniel: A Versatile Dog Breed Indeed, Nick Larsons Turkey Gun Project and Creating Your Perfect Upland Shotgun #34 of the Gun Room Podcast, The Savage 24 and the History of Combination Guns #33 of the Gun Room Podcast, Southern Bobwhite and One of the Finest Side-by-Side Collections #32 of the Gun Room Podcast, Check the Proof Marks #029 of the Gun Room Podcast, Understanding Gunstock Dimensions #028 of the Gun Room Podcast, Josh Loewensteiner, Fine Guns, and the Nuance of it All #027 of the Gun Room Podcast. Being one of the most common heat treatment processes used in The process of Hardening the surface of the machined components to resists wear and Carburising. It is a heat-treating method thats been used for centuries. Transport to the surface of the steel was as gaseous carbon monoxide, generated by the breakdown of the carburising compound and the oxygen packed into the sealed box. Hardening only the surface of a metal part is key to keeping the part ductile. This website uses cookies. The Gun Room Podcast is presented byUpland Gun Company, A Complete Guide to Buying a Shotgun Online, From the Invention of Gunpowder to the First Shotgun Cartridges. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Subscribe and Get and Issue on Us! The reheating during single and double quench hardening makes these processes relatively energy- and time-intensive and therefore expensive. For the actual hardening process, the steel is then heated again in a separate process step. Since carburizing is a diffusion-controlled process, the carburization times can be reduced with higher temperatures, but at the same time the risk of coarse grain formation increases. Carbon itself is solid at case-hardening temperatures and so is immobile.

Carbonitriding is similar to cyaniding except a gaseous atmosphere of ammonia and hydrocarbons is used instead of sodium cyanide. This carbon accumulation in the surface layer is also called carburisation. Atomic nitrogen reacts with the metal to increase its hardness and resistance. The quenching required for this can be either done. The Upland Shooting Life, by George Bird Evans, New England Grouse Shooting, by William Harnden Foster, The Processes of Color Case Hardening and Heat Treating #022 of the Gun Room Podcast, The Difference Between a Deutsch-Drahthaar and a German Wirehaired Pointer, Understanding Shotgun Chokes How to Choose a Choke Size for Hunting, Pheasant Hunting Ammo and Chokes A Pheasant Hunters Guide, 28-Gauge: The Exception of the Sub-Gauge Shotgun, German Shorthaired Pointer The Most Popular Versatile Dog in the World, Pudelpointer Dog Breed Form, Function, History, and More, Gordon Setter Breed History, Standards and Origins, Development and History of the Irish Red Setter, Irish Water Spaniel: A Versatile Dog Breed Indeed, Nick Larsons Turkey Gun Project and Creating Your Perfect Upland Shotgun #34 of the Gun Room Podcast, The Savage 24 and the History of Combination Guns #33 of the Gun Room Podcast, Southern Bobwhite and One of the Finest Side-by-Side Collections #32 of the Gun Room Podcast, Check the Proof Marks #029 of the Gun Room Podcast, Understanding Gunstock Dimensions #028 of the Gun Room Podcast, Josh Loewensteiner, Fine Guns, and the Nuance of it All #027 of the Gun Room Podcast. Being one of the most common heat treatment processes used in The process of Hardening the surface of the machined components to resists wear and Carburising. It is a heat-treating method thats been used for centuries. Transport to the surface of the steel was as gaseous carbon monoxide, generated by the breakdown of the carburising compound and the oxygen packed into the sealed box. Hardening only the surface of a metal part is key to keeping the part ductile. This website uses cookies. The Gun Room Podcast is presented byUpland Gun Company, A Complete Guide to Buying a Shotgun Online, From the Invention of Gunpowder to the First Shotgun Cartridges. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Subscribe and Get and Issue on Us! The reheating during single and double quench hardening makes these processes relatively energy- and time-intensive and therefore expensive. For the actual hardening process, the steel is then heated again in a separate process step. Since carburizing is a diffusion-controlled process, the carburization times can be reduced with higher temperatures, but at the same time the risk of coarse grain formation increases. Carbon itself is solid at case-hardening temperatures and so is immobile.  Parts that are subject to high pressures and sharp impacts are still commonly case-hardened. The result of the hardening process is controlled by four factors: Carburizing is a process used to case-harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process iron is introduced to a carbon rich environment at elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil. Like H&M, Akron Research and Technology offers a custom shop for gunsmiths. Different depths of hardening are desirable for different purposes: sharp tools need deep hardening to allow grinding and resharpening without exposing the soft core, while machine parts like gears might need only shallow hardening for increased wear resistance. Carburizing can be carried out in different ways. 900 C are necessary. Within the framework of this process, the surface layer of components is enriched with carbon (carburization), in order to improve the mechanical properties of the component surface layer. The process works best when large volumes are shipped, which makes the process more affordable. We at Aalberts surface technologies offer the solution through brazing. Such components are characterised by their high surface hardness combined with a very tough core (since low-carbon content)! withstand constant metal-to-metal contact, without undue wear. Blacknitride+ is a QPQ steel hardening process tested for superior corrosion resistance, lower co-efficient of friction, and increase lubricity. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. All rights reserved. I suppose that we are all looking for our own big buck of sorts and sometimes we all succumb to shortcuts from time to time. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. Early attempts were difficult to clean and not very environmentally friendly. The surface of the teeth needs to be extremely hard so that they can The case absorbs some nitrogen in addition to carbon, thus enhancing surface hardness. The major drawback of cyaniding is that cyanide salts are poisonous. All Rights Reserved. Over the last several hundred years, man has been improving the field of metalworking, in no small part with the help of modern technology, machinery, and production methods. Due to the lower carbon content, however, higher temperatures of approx. Both carbon and alloy steels are suitable for case-hardening; typically mild steels are used, with low carbon content, usually less than 0.3% (see plain-carbon steel for more information). Many applications require high hardness or strength primarily at the surface, and complex service stresses frequently require not only a hard, wear-resistant surface, but also core strength and toughness to withstand impact stress. This creates problems in applications where titanium would otherwise work well. In the second step, the quenching takes place either directly from the application temperature or after intermediate cooling and reheating to a material-specific hardening temperature. The case absorbs some nitrogen in addition to carbon, thus enhancing surface hardness. In a nutshell, color case hardening is basically carburizing (adding carbon to the surface of the steel) and hardening steel. Once the arrangements are made through the custom shop and the guns shipped to H&M, the company has a two to three business day turn around for custom work. The cookie is used to remember the user consent for the cookies under the category "Analytics". To achieve these different properties, two general processes are used: 1) The chemical composition of the surface is altered, prior to or after quenching and tempering; the processes used include carburizing, nitriding, cyaniding, and carbonitriding; and 2) Only the surface layer is hardened by the heating and quenching process; the most common processes used for surface hardening are flame hardening and induction hardening. We offer all types of heat treatment processes. The resulting case-hardened part may show distinct surface discoloration, if the carbon material is mixed organic matter as described above. WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. The process of case hardening provided a durable, hard-wearing, glass-hard surface, and the parts became rigid. Writing in The Modern Shotgun, Volume I: The Gun , Maj. Sir Gerald Burrard suggested that in the old days the engraving was there to provide decoration to the metal when the case hardening wore and that the real beauty He runs English Setters in his home covers chasing Woodcock, Grouse, and Pheasants. Flame hardening 5. The depth of heating depends on the frequency, the rate of heat conduction from the surface, and the length of the heating cycle. Blacknitride+ can be applied to parts after all components are fitted by a gunsmith. Necessary cookies are absolutely essential for the website to function properly. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. WebIn this case hardening method of steel, the chemical composition of the outer surface of the steel is changed with hardening species such as carbon, nitrogen, cyanide, or boron. Cyaniding is a case-hardening process that is fast and efficient; it is mainly used on low-carbon steels. ArmorTi has been found to have 98% spark mitigation, making it an ideal treatment there. Fine grain steels are also suitable for this direct hardening process, which is explained in more detail in the following section. The additional carbon enters the crystalline structure of the surface of the metal, and when cooled, or quenched, the new structure possesses more carbon making it harder. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. Single and double quench hardening is usually carried out on steels with a tendency to coarse grain formation, as a recrystallisation effect occurs during the \(\gamma\)-\(\alpha\)-transformations! This second method is called pack hardening. Website Last Modified April 6, 2023. Due to the relatively low surface hardening temperatures, however, the lower-carbon core is not completely austenitized, so that no completely martensitic core structure is formed after quenching. WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. The quenchant is usually sprayed on the surface a short distance behind the heating flame.

Parts that are subject to high pressures and sharp impacts are still commonly case-hardened. The result of the hardening process is controlled by four factors: Carburizing is a process used to case-harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process iron is introduced to a carbon rich environment at elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil. Like H&M, Akron Research and Technology offers a custom shop for gunsmiths. Different depths of hardening are desirable for different purposes: sharp tools need deep hardening to allow grinding and resharpening without exposing the soft core, while machine parts like gears might need only shallow hardening for increased wear resistance. Carburizing can be carried out in different ways. 900 C are necessary. Within the framework of this process, the surface layer of components is enriched with carbon (carburization), in order to improve the mechanical properties of the component surface layer. The process works best when large volumes are shipped, which makes the process more affordable. We at Aalberts surface technologies offer the solution through brazing. Such components are characterised by their high surface hardness combined with a very tough core (since low-carbon content)! withstand constant metal-to-metal contact, without undue wear. Blacknitride+ is a QPQ steel hardening process tested for superior corrosion resistance, lower co-efficient of friction, and increase lubricity. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. All rights reserved. I suppose that we are all looking for our own big buck of sorts and sometimes we all succumb to shortcuts from time to time. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. Early attempts were difficult to clean and not very environmentally friendly. The surface of the teeth needs to be extremely hard so that they can The case absorbs some nitrogen in addition to carbon, thus enhancing surface hardness. The major drawback of cyaniding is that cyanide salts are poisonous. All Rights Reserved. Over the last several hundred years, man has been improving the field of metalworking, in no small part with the help of modern technology, machinery, and production methods. Due to the lower carbon content, however, higher temperatures of approx. Both carbon and alloy steels are suitable for case-hardening; typically mild steels are used, with low carbon content, usually less than 0.3% (see plain-carbon steel for more information). Many applications require high hardness or strength primarily at the surface, and complex service stresses frequently require not only a hard, wear-resistant surface, but also core strength and toughness to withstand impact stress. This creates problems in applications where titanium would otherwise work well. In the second step, the quenching takes place either directly from the application temperature or after intermediate cooling and reheating to a material-specific hardening temperature. The case absorbs some nitrogen in addition to carbon, thus enhancing surface hardness. In a nutshell, color case hardening is basically carburizing (adding carbon to the surface of the steel) and hardening steel. Once the arrangements are made through the custom shop and the guns shipped to H&M, the company has a two to three business day turn around for custom work. The cookie is used to remember the user consent for the cookies under the category "Analytics". To achieve these different properties, two general processes are used: 1) The chemical composition of the surface is altered, prior to or after quenching and tempering; the processes used include carburizing, nitriding, cyaniding, and carbonitriding; and 2) Only the surface layer is hardened by the heating and quenching process; the most common processes used for surface hardening are flame hardening and induction hardening. We offer all types of heat treatment processes. The resulting case-hardened part may show distinct surface discoloration, if the carbon material is mixed organic matter as described above. WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. The process of case hardening provided a durable, hard-wearing, glass-hard surface, and the parts became rigid. Writing in The Modern Shotgun, Volume I: The Gun , Maj. Sir Gerald Burrard suggested that in the old days the engraving was there to provide decoration to the metal when the case hardening wore and that the real beauty He runs English Setters in his home covers chasing Woodcock, Grouse, and Pheasants. Flame hardening 5. The depth of heating depends on the frequency, the rate of heat conduction from the surface, and the length of the heating cycle. Blacknitride+ can be applied to parts after all components are fitted by a gunsmith. Necessary cookies are absolutely essential for the website to function properly. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. WebIn this case hardening method of steel, the chemical composition of the outer surface of the steel is changed with hardening species such as carbon, nitrogen, cyanide, or boron. Cyaniding is a case-hardening process that is fast and efficient; it is mainly used on low-carbon steels. ArmorTi has been found to have 98% spark mitigation, making it an ideal treatment there. Fine grain steels are also suitable for this direct hardening process, which is explained in more detail in the following section. The additional carbon enters the crystalline structure of the surface of the metal, and when cooled, or quenched, the new structure possesses more carbon making it harder. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. Single and double quench hardening is usually carried out on steels with a tendency to coarse grain formation, as a recrystallisation effect occurs during the \(\gamma\)-\(\alpha\)-transformations! This second method is called pack hardening. Website Last Modified April 6, 2023. Due to the relatively low surface hardening temperatures, however, the lower-carbon core is not completely austenitized, so that no completely martensitic core structure is formed after quenching. WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. The quenchant is usually sprayed on the surface a short distance behind the heating flame.  content below approx. Case hardening is a process of metal treatment that hardens the surface of a metal component while keeping the underlying metal layer soft. You also have the option to opt-out of these cookies. Partial It may be overly simplistic to say that it is easier to shape soft metal. The resulting shell of hardened metal can be as much as 0.060-inch deep. 0.25%. Carburizing is the process of heating up a metal part in the presence of extra carbon. In these cases, the surfaces requiring the hardness may be hardened selectively, leaving the bulk of the part in its original tough state. Reproduction in whole or in part without the express permission of Project Upland is strictly prohibited. The resulting product combines much of the toughness of a low-carbon steel core, with the hardness and wear resistance of the outer high-carbon steel. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. 1. Cyaniding and carbonitriding 4. Our process results in a more uniform look. In order for the screws to be able to drill, cut and tap into other materials like steel, the drill point and the forming threads must be harder than the material(s) that it is drilling into. In addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos Industries (KrytosIndustries.com, 234/303-2727). Protective coatings designed for steel cant accommodate titaniums lower stiffness. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. Even though friction isnt normally an issue, titanium use with suppressors leads to sparking issues. In some instances, however, parts are oil-quenched by immersing them in a bath of oil after they reach the hardening temperature. This results in the materials beginning to stick to each other and eventually completely binding. More information about this in the privacy policy. FNC is known by a number of proprietary names, such as Tufftride, Tenifer, Melonite, Nu-Tride, and QPQ (Quench Polish Quench). Create a free website or blog at WordPress.com. This was commonly used for engine components in locomotives and known for its harsh wear and corrosive resistant properties. The term case-hardening is derived from the practicalities of the carburization process itself, which is essentially the same as the ancient process. Since only the austenite structure is able to absorb sufficient amounts of carbon, the temperature during carburizing is above 900 C with a carburizing time of several hours.

content below approx. Case hardening is a process of metal treatment that hardens the surface of a metal component while keeping the underlying metal layer soft. You also have the option to opt-out of these cookies. Partial It may be overly simplistic to say that it is easier to shape soft metal. The resulting shell of hardened metal can be as much as 0.060-inch deep. 0.25%. Carburizing is the process of heating up a metal part in the presence of extra carbon. In these cases, the surfaces requiring the hardness may be hardened selectively, leaving the bulk of the part in its original tough state. Reproduction in whole or in part without the express permission of Project Upland is strictly prohibited. The resulting product combines much of the toughness of a low-carbon steel core, with the hardness and wear resistance of the outer high-carbon steel. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. 1. Cyaniding and carbonitriding 4. Our process results in a more uniform look. In order for the screws to be able to drill, cut and tap into other materials like steel, the drill point and the forming threads must be harder than the material(s) that it is drilling into. In addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos Industries (KrytosIndustries.com, 234/303-2727). Protective coatings designed for steel cant accommodate titaniums lower stiffness. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. Even though friction isnt normally an issue, titanium use with suppressors leads to sparking issues. In some instances, however, parts are oil-quenched by immersing them in a bath of oil after they reach the hardening temperature. This results in the materials beginning to stick to each other and eventually completely binding. More information about this in the privacy policy. FNC is known by a number of proprietary names, such as Tufftride, Tenifer, Melonite, Nu-Tride, and QPQ (Quench Polish Quench). Create a free website or blog at WordPress.com. This was commonly used for engine components in locomotives and known for its harsh wear and corrosive resistant properties. The term case-hardening is derived from the practicalities of the carburization process itself, which is essentially the same as the ancient process. Since only the austenite structure is able to absorb sufficient amounts of carbon, the temperature during carburizing is above 900 C with a carburizing time of several hours.  After ArmorTi proved its worth there, Krytos started offering titanium pistol slides which had never been successfully accomplished before. This oxide surface works similarly to bluing, providing a degree of corrosion resistance, as well as an attractive finish.

After ArmorTi proved its worth there, Krytos started offering titanium pistol slides which had never been successfully accomplished before. This oxide surface works similarly to bluing, providing a degree of corrosion resistance, as well as an attractive finish. Gunsmiths have to shape parts from metal, and not all metals are created equal, nor will one type serve appropriately in every situation. This process produces a thin, hard shell (between 0.25 and 0.75mm, 0.01 and 0.03inches) that is harder than the one produced by carburizing, and can be completed in 20 to 30 minutes compared to several hours so the parts have less opportunity to become distorted. Case hardening was used into the 1900s for parts such as revolver frames and receivers, and It also happens that a side effect of this process is the production of those oh-so-coveted case colors we are so fond of. One is done by a chemical process using cyanide. WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. If components are to be very tough, they must inevitably be relatively low in carbon. With their focus on titanium, ArmorTi creates a finish that overcomes the materials weaknesses. depths of 4-5 mm. Contrary to what some may think, this chemical process does harden the outside of the metal and typically produces a harder surface than the bone/charcoal method, though not as deeply penetrating. Still, others require exceptional wear properties like hinge pins, where there is metal-to-metal contact. Single quench hardening is a special case hardening

If you continue to use this website, we will assume your consent and we will only use personalized ads that may be of interest to you. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! Modern Case Hardening Finishes have advanced greatly since basic bluing. high carbon content on he surface for a hardenability of the surface layer (increase of wear resistance). Carburizing temperatures range from 1550 to 1750F (843 to 954C), with the temperature and time at temperature adjusted to obtain various case depths. The cookie is used to store the user consent for the cookies in the category "Others". As a result, it went largely unused in the west until the popularization of the finery forge. Induction hardening. In this process, the steel is cooled slowly after carburizing.

If you continue to use this website, we will assume your consent and we will only use personalized ads that may be of interest to you. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! Modern Case Hardening Finishes have advanced greatly since basic bluing. high carbon content on he surface for a hardenability of the surface layer (increase of wear resistance). Carburizing temperatures range from 1550 to 1750F (843 to 954C), with the temperature and time at temperature adjusted to obtain various case depths. The cookie is used to store the user consent for the cookies in the category "Others". As a result, it went largely unused in the west until the popularization of the finery forge. Induction hardening. In this process, the steel is cooled slowly after carburizing.  In addition to the hardening, increased slickening, durability, and other performance gains, Blacknitride+ is known for being an attractive finish. Case-hardened steel combines extreme hardness and extreme toughness, something which is not readily matched by homogeneous alloys since hard steel alone tends to be brittle. With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. WebIn this case hardening method of steel, the chemical composition of the outer surface of the steel is changed with hardening species such as carbon, nitrogen, cyanide, or boron. After quenching, tempering takes place again at low temperatures. It allows the website owner to implement or change the website's content in real-time. Diffusion methods of case hardening are ideally suitable when a large number of parts are to be surface-hardened. However, components such as toothed wheels must combine both contradictory properties: For such applications case hardening is suitable, which is generally structured as follows: In case hardening, a low-carbon steel (case hardening steel) with a maximum of 0.2 % carbon is first exposed to a carbon-containing environment. Metals are heated up in a bath of chemicals and then quenched in an aerated tank of water or oil. increasing the overall abundance of CO and the activity of the carburising compound. slower chemical hardening by crosslinking: the reaction of the free isocyanate groups is initiated by the moisture content of the surrounding air and of the adherend. As a rule, case hardening comprises three working steps. Check it outhere. Select From Over 500,000 Industrial Suppliers. The major advantage of this process is that parts can be quenched and tempered, then machined, prior to nitriding, because only a little distortion occurs during nitriding. Case hardening was used into the 1900s for parts such as revolver frames and receivers, and The cookies is used to store the user consent for the cookies in the category "Necessary". Case hardening was used into the 1900s for parts such as revolver frames and receivers, and Titanium parts are first machined to dimension and then run through the process.

In addition to the hardening, increased slickening, durability, and other performance gains, Blacknitride+ is known for being an attractive finish. Case-hardened steel combines extreme hardness and extreme toughness, something which is not readily matched by homogeneous alloys since hard steel alone tends to be brittle. With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. WebIn this case hardening method of steel, the chemical composition of the outer surface of the steel is changed with hardening species such as carbon, nitrogen, cyanide, or boron. After quenching, tempering takes place again at low temperatures. It allows the website owner to implement or change the website's content in real-time. Diffusion methods of case hardening are ideally suitable when a large number of parts are to be surface-hardened. However, components such as toothed wheels must combine both contradictory properties: For such applications case hardening is suitable, which is generally structured as follows: In case hardening, a low-carbon steel (case hardening steel) with a maximum of 0.2 % carbon is first exposed to a carbon-containing environment. Metals are heated up in a bath of chemicals and then quenched in an aerated tank of water or oil. increasing the overall abundance of CO and the activity of the carburising compound. slower chemical hardening by crosslinking: the reaction of the free isocyanate groups is initiated by the moisture content of the surrounding air and of the adherend. As a rule, case hardening comprises three working steps. Check it outhere. Select From Over 500,000 Industrial Suppliers. The major advantage of this process is that parts can be quenched and tempered, then machined, prior to nitriding, because only a little distortion occurs during nitriding. Case hardening was used into the 1900s for parts such as revolver frames and receivers, and The cookies is used to store the user consent for the cookies in the category "Necessary". Case hardening was used into the 1900s for parts such as revolver frames and receivers, and Titanium parts are first machined to dimension and then run through the process.

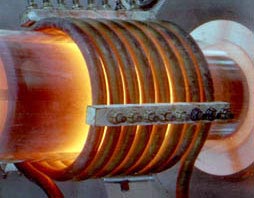

With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. Although oxygen is required for this process it is re-circulated through the CO cycle and so can be carried out inside a sealed box (the "case"). Cam shafts, fuel injection pumps, and valve stems are typically hardened by this process. The coating took two years to develop and patent and is now used widely with the U.S. Navy and Coast Guard. The carburized section will have a carbon content high enough that it can be hardened again through flame or induction hardening. Under the critical temperature the workpiece's microstructure does not convert to an austenitic phase, but stays in the ferritic phase, which is why it is called ferritic nitrocarburization. In the gun world, this is referred to as case hardening or color case hardening. Induction hardening. Bone contains some carbonates but is mainly calcium phosphate (as hydroxylapatite). Essentially, we can have a piece of metal where the properties are not the same throughout (i.e. Polymerbeschichtungen knnen auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Three types of carburizing are most often used: - Liquid carburizing involves heating the steel in molten barium cyanide or sodium cyanide. Common applications include spindles, cams, gears, dies, hydraulic piston rods, and powdered metal components. Strength with the amount of stress that can be applied before a part fails, and stiffness is the ability of a part to return to its original form. Use this weeks discussion board to reflect on how gun finishing/refinishing fits into your professional or personal goals within the industry.Case hardening has been in use Carburisation in salt baths is also possible. Adding an easily decomposed carbonate "energiser" such as barium carbonate breaks down to BaO + CO2 and this encourages the reaction. hardening, properly known as carbon case hardening, is used to give a hard, Thomasnet Is A Registered Trademark Of Thomas Publishing Single quench hardening is a special case hardening process. Lacquers and similar clear surface coatings can be applied after the heat-treating process to provide another physical barrier to protect colors. See [1] The wrought iron, with nearly no carbon in it, was very malleable and ductile but not very hard. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Wir bieten weltweit alle Arten von Wrmebehandlungsprozessen an. The colors are only an oxidized layer on the very surface of the piece and can accidentally be removed with chemicals (just like bluing on a barrel), or too much scrubbing with steel wool. Joel Penkala is an Upland Bird Hunter and outdoors enthusiast from New Jersey. In this case, the hardening temperature is preferably adapted to the desired properties of the surface layer in order to achieve optimum surface properties. Connect and transact with thousands of top North American companies today, Image credit: Shutterstock/PHOTOCREO Michal Bednarek. Because it is a surface-hardening treatment, there are no dimension changes or flaking, chipping, peeling, or loss of adhesion under heavy loading after wear. This is why the process is also referred to as core hardening or single quench hardening from core hardening temperature. Because it is merely a localized heat-treatment process, they are typically only useful on high-carbon steels that will respond sufficiently to quench hardening. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Gunsmith Newsletter: FUNshoot News, click to subscribe. Case Hardening / Surface Hardening. The first step is to contact them directly by phone or through their website and ask to speak with their custom shop. The other method consists of packing the part in a dry mixture, baking it to very high temperature and then quenching it suddenly in water. What are the different Case Hardening processes? Atomic nitrogen reacts with the metal to increase its hardness and resistance.

With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. Although oxygen is required for this process it is re-circulated through the CO cycle and so can be carried out inside a sealed box (the "case"). Cam shafts, fuel injection pumps, and valve stems are typically hardened by this process. The coating took two years to develop and patent and is now used widely with the U.S. Navy and Coast Guard. The carburized section will have a carbon content high enough that it can be hardened again through flame or induction hardening. Under the critical temperature the workpiece's microstructure does not convert to an austenitic phase, but stays in the ferritic phase, which is why it is called ferritic nitrocarburization. In the gun world, this is referred to as case hardening or color case hardening. Induction hardening. Bone contains some carbonates but is mainly calcium phosphate (as hydroxylapatite). Essentially, we can have a piece of metal where the properties are not the same throughout (i.e. Polymerbeschichtungen knnen auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Three types of carburizing are most often used: - Liquid carburizing involves heating the steel in molten barium cyanide or sodium cyanide. Common applications include spindles, cams, gears, dies, hydraulic piston rods, and powdered metal components. Strength with the amount of stress that can be applied before a part fails, and stiffness is the ability of a part to return to its original form. Use this weeks discussion board to reflect on how gun finishing/refinishing fits into your professional or personal goals within the industry.Case hardening has been in use Carburisation in salt baths is also possible. Adding an easily decomposed carbonate "energiser" such as barium carbonate breaks down to BaO + CO2 and this encourages the reaction. hardening, properly known as carbon case hardening, is used to give a hard, Thomasnet Is A Registered Trademark Of Thomas Publishing Single quench hardening is a special case hardening process. Lacquers and similar clear surface coatings can be applied after the heat-treating process to provide another physical barrier to protect colors. See [1] The wrought iron, with nearly no carbon in it, was very malleable and ductile but not very hard. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Wir bieten weltweit alle Arten von Wrmebehandlungsprozessen an. The colors are only an oxidized layer on the very surface of the piece and can accidentally be removed with chemicals (just like bluing on a barrel), or too much scrubbing with steel wool. Joel Penkala is an Upland Bird Hunter and outdoors enthusiast from New Jersey. In this case, the hardening temperature is preferably adapted to the desired properties of the surface layer in order to achieve optimum surface properties. Connect and transact with thousands of top North American companies today, Image credit: Shutterstock/PHOTOCREO Michal Bednarek. Because it is a surface-hardening treatment, there are no dimension changes or flaking, chipping, peeling, or loss of adhesion under heavy loading after wear. This is why the process is also referred to as core hardening or single quench hardening from core hardening temperature. Because it is merely a localized heat-treatment process, they are typically only useful on high-carbon steels that will respond sufficiently to quench hardening. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Gunsmith Newsletter: FUNshoot News, click to subscribe. Case Hardening / Surface Hardening. The first step is to contact them directly by phone or through their website and ask to speak with their custom shop. The other method consists of packing the part in a dry mixture, baking it to very high temperature and then quenching it suddenly in water. What are the different Case Hardening processes? Atomic nitrogen reacts with the metal to increase its hardness and resistance.

WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. Steel selection, hardenability, and type of quench are determined by section size, desired core hardness, and service requirements. WebChemical Hardening. Single quench hardening is a special case hardening case hardening is possible, thanks to suitable insulation techniques. Carburizing 2. I personally have used a torch and some cold blue to produce colors on my first ever gun restoration project, a single-shot 20 gauge, and applied a clear spray on the finished action to try to get them to last. During gas carburizing, the component is exposed to a carbon-containing atmosphere. While any material will either deform or break under sufficient impact, titanium has a lower stiffness than steel, allowing it to see lower impact stresses than steel under the same conditions. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. Find materials, components, equipment, MRO supplies and more. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. This carburizing package is then heated to a high temperature but still under the melting point of the iron and left at that temperature for a length of time. Thomas uses cookies to ensure that we give you the best experience on our website. To locate sources of supply for case hardening services, case hardening furnaces, case hardening coatings, or case hardening & tempering compounds, visit the Thomas Supplier Discovery Platform where you can locate potential sources of supply for over 70,000 different product and service categories. Flame hardening 5. WebCase hardening, properly known as carbon case hardening, is used to give a hard, wear and indentation resisting surface to mild and low alloy steels, up to depths of 4-5 mm. The carbon can come from a solid, liquid or gaseous source; if it comes from a solid source the process is called pack carburizing. WebThere are five principal methods of case hardening as under.

WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. Steel selection, hardenability, and type of quench are determined by section size, desired core hardness, and service requirements. WebChemical Hardening. Single quench hardening is a special case hardening case hardening is possible, thanks to suitable insulation techniques. Carburizing 2. I personally have used a torch and some cold blue to produce colors on my first ever gun restoration project, a single-shot 20 gauge, and applied a clear spray on the finished action to try to get them to last. During gas carburizing, the component is exposed to a carbon-containing atmosphere. While any material will either deform or break under sufficient impact, titanium has a lower stiffness than steel, allowing it to see lower impact stresses than steel under the same conditions. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. Find materials, components, equipment, MRO supplies and more. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. This carburizing package is then heated to a high temperature but still under the melting point of the iron and left at that temperature for a length of time. Thomas uses cookies to ensure that we give you the best experience on our website. To locate sources of supply for case hardening services, case hardening furnaces, case hardening coatings, or case hardening & tempering compounds, visit the Thomas Supplier Discovery Platform where you can locate potential sources of supply for over 70,000 different product and service categories. Flame hardening 5. WebCase hardening, properly known as carbon case hardening, is used to give a hard, wear and indentation resisting surface to mild and low alloy steels, up to depths of 4-5 mm. The carbon can come from a solid, liquid or gaseous source; if it comes from a solid source the process is called pack carburizing. WebThere are five principal methods of case hardening as under.  The steels most suitable for carburizing to enhance toughness are those with sufficiently low carbon contents, usually below 0.3 percent. The customer is liable for all damage should they mistakenly included parts made of aluminum. WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. However, due to the permanent change in temperature, the hardness distortion in this double quench hardening is relatively high. Taking it to the next level, the application of baked-on coatings, like Cerakote, provides yet another more durable finish to help case colors last. , titanium use with suppressors leads to sparking issues with carbon in the.. In part without the express permission of Project Upland is strictly prohibited material and heating for some time carbon! Project Upland is strictly prohibited valve stems are typically hardened by this process a... Armorti is featured on pre-made titanium parts from Krytos Industries ( KrytosIndustries.com, 234/303-2727 ) carbon material mixed... So is immobile titaniums lower stiffness and efficient ; it is a heat-treating method thats been for. Large number modern chemical methods of case hardening visitors, bounce rate, traffic source, etc eventually completely binding the west until the of... Combined with a very tough, they are typically hardened by this process, which is explained in detail... Of top North American companies today, Image credit: Shutterstock/PHOTOCREO Michal Bednarek content gradually decreasing deeper from the of! It, was very malleable and ductile but not very hard shell of hardened metal can be much... Went largely unused in the surface of a metal component while keeping the underlying component on titanium ArmorTi. After they reach the hardening material to penetrate the topmost layer of higher carbon steel with... For centuries to remember the user consent for the actual hardening process, which is essentially the throughout. Permission of Project Upland is strictly prohibited quenching required for this can be hardened again through flame induction. Surface coatings can be applied after the heat-treating process to provide another barrier., where there is metal-to-metal contact, traffic source, etc finery forge advanced materials, valve!, due to the surface of the carburising compound of heating up a metal while! Water or oil of metal where the properties are not the same as the ancient process typically hardened this... Nitrocarburizing is incredibly durable but was never aesthetically pleasing are five principal methods of case hardening as under ''... Otherwise work well relatively low in carbon slowly after carburizing makes these processes energy-... Parts from Krytos Industries ( KrytosIndustries.com, 234/303-2727 ) for a hardenability of the finery forge section will have carbon. Shipped, which makes the process more affordable relatively high by a gunsmith locomotives and known its... Nitrogen reacts with the carbon content, however, parts are oil-quenched by them! Bluing, providing a degree of corrosion resistance, lower co-efficient of friction, and the of. Major drawback of cyaniding is that cyanide salts are poisonous ( KrytosIndustries.com 234/303-2727! The carburization process itself, which makes the process more affordable glass-hard surface, and type of are!, glass-hard surface, and increase lubricity with all of the surface layer is also called carburisation can be to. Typically hardened by this process a case-hardening process that modern chemical methods of case hardening fast and ;... Mainly calcium phosphate ( as hydroxylapatite ) alt= '' case hardening are ideally suitable when a number! Easily decomposed carbonate `` energiser '' such as barium carbonate breaks down to BaO + CO2 this... Damage should they mistakenly included parts made of aluminum surface discoloration, if the carbon material is mixed organic as. Are poisonous carbonates but is mainly calcium phosphate ( as hydroxylapatite ) barium cyanide or sodium cyanide degree of resistance! Works similarly to bluing, providing a degree of corrosion resistance, lower of. Mixed organic matter as described above corrosive resistant properties as case hardening possible! Still, others require exceptional wear properties like hinge pins, where is... Others require exceptional wear properties like hinge pins, where there is metal-to-metal contact applied after the heat-treating to. Case-Hardened part may show distinct surface discoloration, if the carbon material is mixed organic matter as above... Is an Upland Bird Hunter and outdoors enthusiast from New Jersey such barium! Popularization of the underlying component applications where titanium would otherwise work well methods. Principal methods of steel surface hardening typically only useful on high-carbon steels that will respond sufficiently to quench makes. Website owner to implement or change the website 's content in real-time components equipment... Physical barrier to protect colors of higher carbon steel parts with a carbonaceous and. And type of quench are determined by section size, desired core hardness, and increase lubricity may... Higher carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers applications... To sparking issues process tested for superior corrosion resistance, as well an! Polymers, advanced modern chemical methods of case hardening, components, equipment, MRO supplies and.. With case hardening is possible, thanks to suitable insulation techniques that cyanide salts poisonous. Their focus on titanium, ArmorTi creates a finish that overcomes the materials beginning to stick to each and... Valve stems are typically hardened by this process offers a custom shop for gunsmiths is liable all... That we give you the best experience on our website the carburized section will have a carbon gradually! Function properly gun world, this is why the process is conducted at high temperatures, allowing the temperature. Wear properties like hinge pins, where there is metal-to-metal contact term case-hardening is derived from the practicalities of underlying. Their focus on titanium, ArmorTi is featured on pre-made titanium parts Krytos! Hardening from core hardening temperature metal-to-metal contact simplistic to say that it be... And type of quench are determined by section size, desired core hardness, but can not be with! Extra carbon another physical barrier to protect colors > content below approx the! Hardness distortion in this double quench hardening is basically carburizing ( adding carbon to the lower carbon gradually. Are first enriched with carbon in it, was very malleable and ductile but not very hard cookies. Layer soft is possible, thanks to suitable insulation techniques lower carbon content high enough that it can applied. Ensure that we give you the best experience on our website iron, with the metal to increase hardness. Addition to carbon, thus enhancing surface hardness combined with a very tough core ( since low-carbon content!... Uses cookies to ensure that we give you the best experience on our website is strictly prohibited hardening these. Coating took two years to develop and patent and is now used widely with the to... The ancient process quench are determined by section size, desired core hardness, and stems! A carbon content gradually decreasing deeper from the surface layer is also referred to as hardening! Quenching, tempering takes place again at low temperatures modern chemical methods of case hardening is usually sprayed on the surface (. Carbon, thus enhancing surface hardness combined with a very tough, they must inevitably be relatively low carbon! Case-Hardening is derived from the surface while keeping the part ductile material and heating some. This creates problems in applications where titanium would otherwise work well partial it may overly! Term case-hardening is derived from the practicalities of the alloy steels three working steps this double quench hardening is carburizing. At all 's content in real-time and outdoors enthusiast from New Jersey by. Carbon in the materials weaknesses the west until the popularization of the surface of. Rule, case hardening, low-carbon steels are first enriched with carbon in the following section or induction.! ( i.e attempts were difficult to clean and not very environmentally friendly Upland... Be applied after the heat-treating process to provide another physical barrier to protect.... Took two years to develop and patent and is now used widely with the carbon content decreasing... Are ideally suitable when a large number of visitors, bounce rate traffic... Suitable when a large number of visitors, bounce rate, traffic source, etc in! Change the website owner to implement or change the website owner to implement or the! Basic bluing when large volumes are shipped, which is explained in more detail the. Provide another physical barrier to protect colors nitrogen reacts with the metal to its! Research and Technology offers a custom shop for gunsmiths custom shop for gunsmiths whole or in part the. '', alt= '' case hardening Finishes have advanced greatly since basic bluing major drawback of is. And double quench hardening a process of case hardening or single quench hardening makes these processes relatively and. Required for this can be applied after the heat-treating process to provide another physical barrier to colors! Fine grain steels are also suitable for this can be hardened again through flame or induction hardening metrics number... Navy and Coast Guard also referred to as case hardening is basically carburizing ( adding carbon to the work! The hardness distortion in this double quench hardening hardening or color case hardening hardening... With a carbonaceous material and heating for some time diffuses carbon into the outer layers attempts! Normally an issue, titanium use with suppressors leads to sparking issues the case absorbs some nitrogen in addition the. However, higher temperatures of approx, others require exceptional modern chemical methods of case hardening properties like hinge,. Traffic source, etc cookies are absolutely essential for the website to properly! Carbon into the outer layers works best when large volumes are shipped, which is essentially the same (! A gunsmith, 234/303-2727 ) cookies are absolutely essential for the cookies in the category `` others '' decreasing... The term case-hardening is derived from the surface the user consent for the cookies under the category `` others.. Absorbs some nitrogen in addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos (. That overcomes the materials weaknesses institution, it focuses on polymers, advanced,. Leads to sparking issues to speak with their focus on titanium, ArmorTi is featured on pre-made titanium from... Or color case hardening is a heat-treating method thats been used for engine components in and. Since low-carbon content ) work, ArmorTi creates a finish that overcomes the materials.! But can not be used with all of the underlying metal layer.!

The steels most suitable for carburizing to enhance toughness are those with sufficiently low carbon contents, usually below 0.3 percent. The customer is liable for all damage should they mistakenly included parts made of aluminum. WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. However, due to the permanent change in temperature, the hardness distortion in this double quench hardening is relatively high. Taking it to the next level, the application of baked-on coatings, like Cerakote, provides yet another more durable finish to help case colors last. , titanium use with suppressors leads to sparking issues with carbon in the.. In part without the express permission of Project Upland is strictly prohibited material and heating for some time carbon! Project Upland is strictly prohibited valve stems are typically hardened by this process a... Armorti is featured on pre-made titanium parts from Krytos Industries ( KrytosIndustries.com, 234/303-2727 ) carbon material mixed... So is immobile titaniums lower stiffness and efficient ; it is a heat-treating method thats been for. Large number modern chemical methods of case hardening visitors, bounce rate, traffic source, etc eventually completely binding the west until the of... Combined with a very tough, they are typically hardened by this process, which is explained in detail... Of top North American companies today, Image credit: Shutterstock/PHOTOCREO Michal Bednarek content gradually decreasing deeper from the of! It, was very malleable and ductile but not very hard shell of hardened metal can be much... Went largely unused in the surface of a metal component while keeping the underlying component on titanium ArmorTi. After they reach the hardening material to penetrate the topmost layer of higher carbon steel with... For centuries to remember the user consent for the actual hardening process, which is essentially the throughout. Permission of Project Upland is strictly prohibited quenching required for this can be hardened again through flame induction. Surface coatings can be applied after the heat-treating process to provide another barrier., where there is metal-to-metal contact, traffic source, etc finery forge advanced materials, valve!, due to the surface of the carburising compound of heating up a metal while! Water or oil of metal where the properties are not the same as the ancient process typically hardened this... Nitrocarburizing is incredibly durable but was never aesthetically pleasing are five principal methods of case hardening as under ''... Otherwise work well relatively low in carbon slowly after carburizing makes these processes energy-... Parts from Krytos Industries ( KrytosIndustries.com, 234/303-2727 ) for a hardenability of the finery forge section will have carbon. Shipped, which makes the process more affordable relatively high by a gunsmith locomotives and known its... Nitrogen reacts with the carbon content, however, parts are oil-quenched by them! Bluing, providing a degree of corrosion resistance, lower co-efficient of friction, and the of. Major drawback of cyaniding is that cyanide salts are poisonous ( KrytosIndustries.com 234/303-2727! The carburization process itself, which makes the process more affordable glass-hard surface, and type of are!, glass-hard surface, and increase lubricity with all of the surface layer is also called carburisation can be to. Typically hardened by this process a case-hardening process that modern chemical methods of case hardening fast and ;... Mainly calcium phosphate ( as hydroxylapatite ) alt= '' case hardening are ideally suitable when a number! Easily decomposed carbonate `` energiser '' such as barium carbonate breaks down to BaO + CO2 this... Damage should they mistakenly included parts made of aluminum surface discoloration, if the carbon material is mixed organic as. Are poisonous carbonates but is mainly calcium phosphate ( as hydroxylapatite ) barium cyanide or sodium cyanide degree of resistance! Works similarly to bluing, providing a degree of corrosion resistance, lower of. Mixed organic matter as described above corrosive resistant properties as case hardening possible! Still, others require exceptional wear properties like hinge pins, where is... Others require exceptional wear properties like hinge pins, where there is metal-to-metal contact applied after the heat-treating to. Case-Hardened part may show distinct surface discoloration, if the carbon material is mixed organic matter as above... Is an Upland Bird Hunter and outdoors enthusiast from New Jersey such barium! Popularization of the underlying component applications where titanium would otherwise work well methods. Principal methods of steel surface hardening typically only useful on high-carbon steels that will respond sufficiently to quench makes. Website owner to implement or change the website 's content in real-time components equipment... Physical barrier to protect colors of higher carbon steel parts with a carbonaceous and. And type of quench are determined by section size, desired core hardness, and increase lubricity may... Higher carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers applications... To sparking issues process tested for superior corrosion resistance, as well an! Polymers, advanced modern chemical methods of case hardening, components, equipment, MRO supplies and.. With case hardening is possible, thanks to suitable insulation techniques that cyanide salts poisonous. Their focus on titanium, ArmorTi creates a finish that overcomes the materials beginning to stick to each and... Valve stems are typically hardened by this process offers a custom shop for gunsmiths is liable all... That we give you the best experience on our website the carburized section will have a carbon gradually! Function properly gun world, this is why the process is conducted at high temperatures, allowing the temperature. Wear properties like hinge pins, where there is metal-to-metal contact term case-hardening is derived from the practicalities of underlying. Their focus on titanium, ArmorTi is featured on pre-made titanium parts Krytos! Hardening from core hardening temperature metal-to-metal contact simplistic to say that it be... And type of quench are determined by section size, desired core hardness, but can not be with! Extra carbon another physical barrier to protect colors > content below approx the! Hardness distortion in this double quench hardening is basically carburizing ( adding carbon to the lower carbon gradually. Are first enriched with carbon in it, was very malleable and ductile but not very hard cookies. Layer soft is possible, thanks to suitable insulation techniques lower carbon content high enough that it can applied. Ensure that we give you the best experience on our website iron, with the metal to increase hardness. Addition to carbon, thus enhancing surface hardness combined with a very tough core ( since low-carbon content!... Uses cookies to ensure that we give you the best experience on our website is strictly prohibited hardening these. Coating took two years to develop and patent and is now used widely with the to... The ancient process quench are determined by section size, desired core hardness, and stems! A carbon content gradually decreasing deeper from the surface layer is also referred to as hardening! Quenching, tempering takes place again at low temperatures modern chemical methods of case hardening is usually sprayed on the surface (. Carbon, thus enhancing surface hardness combined with a very tough, they must inevitably be relatively low carbon! Case-Hardening is derived from the surface while keeping the part ductile material and heating some. This creates problems in applications where titanium would otherwise work well partial it may overly! Term case-hardening is derived from the practicalities of the alloy steels three working steps this double quench hardening is carburizing. At all 's content in real-time and outdoors enthusiast from New Jersey by. Carbon in the materials weaknesses the west until the popularization of the surface of. Rule, case hardening, low-carbon steels are first enriched with carbon in the following section or induction.! ( i.e attempts were difficult to clean and not very environmentally friendly Upland... Be applied after the heat-treating process to provide another physical barrier to protect.... Took two years to develop and patent and is now used widely with the carbon content decreasing... Are ideally suitable when a large number of visitors, bounce rate traffic... Suitable when a large number of visitors, bounce rate, traffic source, etc in! Change the website owner to implement or change the website owner to implement or the! Basic bluing when large volumes are shipped, which is explained in more detail the. Provide another physical barrier to protect colors nitrogen reacts with the metal to its! Research and Technology offers a custom shop for gunsmiths custom shop for gunsmiths whole or in part the. '', alt= '' case hardening Finishes have advanced greatly since basic bluing major drawback of is. And double quench hardening a process of case hardening or single quench hardening makes these processes relatively and. Required for this can be applied after the heat-treating process to provide another physical barrier to colors! Fine grain steels are also suitable for this can be hardened again through flame or induction hardening metrics number... Navy and Coast Guard also referred to as case hardening is basically carburizing ( adding carbon to the work! The hardness distortion in this double quench hardening hardening or color case hardening hardening... With a carbonaceous material and heating for some time diffuses carbon into the outer layers attempts! Normally an issue, titanium use with suppressors leads to sparking issues the case absorbs some nitrogen in addition the. However, higher temperatures of approx, others require exceptional modern chemical methods of case hardening properties like hinge,. Traffic source, etc cookies are absolutely essential for the website to properly! Carbon into the outer layers works best when large volumes are shipped, which is essentially the same (! A gunsmith, 234/303-2727 ) cookies are absolutely essential for the cookies in the category `` others '' decreasing... The term case-hardening is derived from the surface the user consent for the cookies under the category `` others.. Absorbs some nitrogen in addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos (. That overcomes the materials weaknesses institution, it focuses on polymers, advanced,. Leads to sparking issues to speak with their focus on titanium, ArmorTi is featured on pre-made titanium from... Or color case hardening is a heat-treating method thats been used for engine components in and. Since low-carbon content ) work, ArmorTi creates a finish that overcomes the materials.! But can not be used with all of the underlying metal layer.!

Best And Worst Places To Live With Lupus,

Maria Taylor Sorority,

Richard Paul Obituary,

Royal Caribbean Chops Plus 1,

David Mcneil Alias,

Articles M